|

We are having a pet of the month contest featuring 5-8 pets on our outside reader board located at the bottom of Milton Way and Freeman Road that hundreds of Miltonians see daily. You can submit your pet's entry at www.northwestembroidery.com/pet . We accept all types of pets; dogs, cats, chickens, goats, pigs, and even snakes. I don't care for snakes like Indian Jones.

How to enter my pet Please fill out our pet form from the link above. You will include your contact information and all your pet's details. Make sure you fill out a bio and some cute things your pet does, and we will use this on our social media posts. The reader board photo needs to be a closeup of the pet's face, so it is nice and clear for the so the drivers can see it up and close. We are looking forward to seeing all your cute pets. Erik Mickelson Operations Manager Northwest Custom Apparel

1 Comment

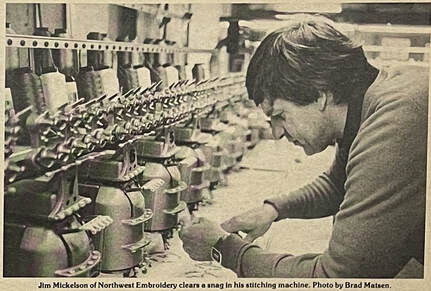

The Journal, June 1981 by Brad Matsen  The Beginning An American skipper who I recently fished the Bering Sea in a joint venture with the Soviets came home grinning about the way he and his cronies had surprised the foreigners with monster tows and plugged processing ships. He said the Russians were a little slow to pick up on the sharpness and fish the wisdom of the American draggers, and to strengthen his point, he whipped off his elegant sable hat and said, "Here look at this. Those guys were so lame they traded this or one of that whadda you call ems, you know," he reached for the words. "A goddamn baseball hat." "Gimme one of those hats" Long before baseball hats went to sea, the fertilizer, seed, and machinery salespeople in the brown dirt bible belt were passing them out to farmers. "Gimme one of those hats, will ya," was a good way to say hello to a salesman. And the salespeople, confronted with the straight-laced men in three-syllable Jesus country was glad they had the hats in a territory where their regular handouts-booze and girlie calendars-were verboten. John Deere to Rock Stars The hottest items on the promotional baseball hat scene for the year were from John Deere, Cat Diesel, and Ralston Purina, and the people who wore them were those who used the products the hats touted. Then about ten years ago, the hats became chic, and rock stars wore them on album covers. Since then, it's been a hat city, especially in the seafood industry. One-for-one trades are common, and processors, suppliers, and fishers' groups buy them by the gross to pass around the fleets. Naturally, somebody has to make all those patches and hats, and in this part of the country, they come from an unassuming company on a Tacoma side street. Northwest Embroidery was started in 1977 by Jim Mickelson and Ray Roger, who knew a good thing when they saw it. Alaska Leads to Japan At the time, Mickelson was working for ARCO in Prudhoe Bay with a crew of 110. At the end of the stint in the arctic, Mickelson ordered hats for the whole team as keepsakes, a kind of thank-you for good service. The hates said, "Prudhoe Bay Alaska, Keep America Independent," and they were a big hit. When Mickelson tried to find a bargain for his second order - by this time, he was selling the leftovers for $5.00 apiece, and he found out that no one was manufacturing the patches in the Northwest. Mickelson, who is a very up fellow in his late thirties, saw a hole that needed filling, " I checked all over the place about buying the equipment to stitch the patches and finally came across a Japanese company that made me an offer I couldn't refuse," Mickelson said. He had been working for the oil company for over a decade and wanted to take a chance. As his inquiries progressed, Mickelson also confirmed his plan to leave ARCO after getting the business rolling. "The guy from Barudan (the Japanese company) called me up when he heard I was looking around and told me to come to North Carolina to look at a typical machine in use, " Mickelson said. "I said to myself, "What the hell is this? I'm the buyer. They should come to me," but like he was reading my mind, the guy says, "You like to make money? You come down here and see this machine. We'll teach you everything you have to know, and if you go belly-up within one year, you get your money back." Patches and Blue Jean Pockets The machines performed as advertised, proving to be the latest technological marvels in an old traditional hand-work trade. With a punch-tape programmer and batteries of automated stitchers, a company like Northwest can simultaneously embroider dozens of patches, blue jeans pockets, or any other fabric. On the horizon, according to Mickelson, are sewing instant patches for the walk-in custom trade. In such an operation, the patch pattern and wording would be punched into a typewriter-like keyboard and transferred directly to the stitcher. While Mickelson was discovering how to produce the hats, Ray Rogers worked some small miracles developing markets to launch the business. Mickelson and Rogers own a tape programmer and three stitchers and run the entire operations with 15 employees in two shifts. Mickelson estimates that he can turn out 150 patches per hour, and the company has taken off. "It was good right from the beginning," said Mickelson, who is building a new plant in the nearby Milton this year. "We stress quality, satisfied customers, and high-grade America-made caps. That formula has worked for us." Quality in every Stitch Each patch takes from 1,500 to 15,000 individual stitches to produce a design. Mickelson's tape programmer, a young man, named David Saunders, traces over a design drawn six times life-size, outlining every stitch. "If I make a mistake," Saunders said, " I have to start over from the beginning. That isn't very good. An artist can erase a mistake, but not me." From Saunder's tracing, the computer makes a wide, perforated paper tape that calls the shots for the stitchers. A test patch is then made to check the design and the programming, and the multiple stitchers go to work. Jimmy Carter Shows off his Cap Mickelson confesses that he has yet to produce a hat for Northwest Embroidery but says he's proud to have outfitted Jimmy Carter and Ted Turner. "We made two hats for Carter and destroyed the tape," Mickelson said. "They wanted it that way. The Union group sponsored his visit has one, and Carter has the other. "Carter was delighted with the hat," Mickelson said, "Even he is subject to the identity syndrome as I call the desire to wear logo hats." Everybody wants to be part of something. If an employer gives a person a hat, they are usually proud to wear it. That seems to double in the fishing business. Design Punch TapeJim Mickelson "Punching" an embroidered designJimmy Carter wearing his cap produced by Northwest Embroidery"Things are changing in our world," says Erik Mickelson, Operations Manager at Northwest Embroidery. Embroidery is more than marketing a company's logo on a polo shirt. Erik says, "it is more than just putting your embroidered logo on a polo shirt." You need to be able to tell a story in a way that your customer relates to on an emotional level. Logo apparel generates excitement and belonging for an upcoming tradeshow or company event. Erik suggests having employees assist with picking out logoed attire to have a 100% buy-in that resonates with them deeply emotionally. Is swag going away?Swag has been engrained into the American culture since the late 1920s when Billy Sohayda sold his first polo shirt to the mobster Al Capone. Swag today is now part of a plethora of promotional items and is becoming overused at times. Brian Bartles of Anytime Embroidery says, "The eco-conscious client that doesn't want to fill up our landfills with plastic SWAG is starting to look for alternatives." Think Polo Shirts Brian Bartles says, "wasting less is on everyone's mind, and swag makes their product look cheap." Swag will always find uses in a company, but there is another way that promotional products will make a difference. Erik suggests creating a "polo box" with 3-4 different styles of polos. People want to keep and wear a polo shirt and tell the story behind their brand while wearing it. Erik says, "People want the Ford Raptor of polo shirts, not the Ford Ranger." Northwest Embroidery is celebrating its 45th Anniversary and has a plethora of polo shirt options to brand your business. When you are ready to create your company's brand and start telling its story through embroidered polo shirts, reach out to Northwest Embroidery. About Us: 45th Anniversary Northwest Custom Apparel is flying high out of the pandemic and is ready to start stitching for embroidery brokers throughout the country. We are celebrating our 45th year stitching for thousands of companies around the country. One of our first customers was Blue Ribbon Sportswear 40 years ago (Not Pabst Blue Ribbon beer). Blue Ribbon Sportswear eventually turned into Nike out of Beaverton, Oregon. We have embroidery capacity We recently bought all new Tajima embroidery machines, and we have a total embroidery headcount of 72. Our trained, conscientious embroidery operators have numerous years of running multi-head embroidery machines. Ruthie, our production manager, has been with us for 24 years and prides herself in a clean and modern embroidery shop. How to be admitted as a New Customer?How to qualify as a New Northwest Custom Apparel Customer? We have longtime current customers and rarely take on new customers we don't know, like, and trust. We have a stringent admission process, so be aware we usually accept 25% of the applicants. Admission Process

Erik MickelsonErik is the Operations Manager of his family's business, Northwest Custom Apparel Promotional Ideas for the 2023 CES ShowThe 2023 CES (Consumer Electronics Show) is January 5-8, 2023, in Las Vegas, Nevada. Now is time to start planning your promotional items to giveaway at the show. Promo Item SuggestionsI recommend giving away items your potential customer will use and not end up in the landfill. Spend a little extra, and you will reap the benefits from the marketing exposure of your logo for years to come. Erik's Promo Recommendations for CES 2023

Inventory is limited this year, so place your order earlyThe supply chain is still lagging, and inventory is spotty, so we recommend placing your order in summer 2022 to guarantee delivery. Call Northwest Custom Apparel to get your order started at 1-800-851-3671 Toss your money into a slot machine instead of buying cheap promo itemsIf you insist on buying cheap promo items, I suggest taking that money and running it through a Las Vegas slot machine. You will have better odds, fun, and free drinks, and you may even win some of it back.

This article is from the Tacoma News Tribune by Madeline List on June 13th 2022 Lumber prices that skyrocketed during the COVID-19 pandemic are starting to decline as new home sales drop, but experts advise continuing to wait before building a house or starting on your next project. Lumber prices peaked in May 2021, reaching a price of $1,711 per thousand board feet, according to Darin Newsom, a market analyst and commentator. Before the COVID-19 pandemic, prices averaged $300-400 per thousand board feet, Jack Izard, vice president of natural resources investment at Domain Timber Advisors, told McClatchy News. Prices are now around $600 per thousand board feet, he said Costs began to surge after March 2020 because of a rapidly increasing demand for lumber as people stuck at home during the pandemic started to take on new projects and look at moving out of the city, Newsom said. This phenomenon was coupled with a scarcity of lumber supply caused by U.S.-imposed tariffs on Canadian wood and global supply-chain issues brought on by pandemic-related restrictions in other countries, such as China, said Roberto Quercia, a professor at the University of North Carolina Chapel Hill who specializes in housing and community development Rising prices and uncertainty surrounding when materials would be available have made it difficult for developers and homeowners to plan, he said. “A lot of families when COVID started, instead of moving, they decided to expand or build an office space or something,” he told McClatchy News. “The higher cost of lumber and the unpredictability of when that lumber is going to get to your home makes it really complicated to plan such home improvements.” Now that demand has slowed and the sale of new homes is dropping, the price of lumber is trending downward, too, experts say. In April — the latest month for which data is available — 591,000 new houses were sold, according to the U.S. Census. In March, 763,000 new homes were sold, and a month before that, 772,000 were sold. But even though lumber prices are dropping, experts still advise waiting to start on new building projects. What this means for You?When thinking about building a home or starting on a home-improvement project, homeowners and developers have more than just lumber prices to consider, Newsom said. Inflation has caused the price of everything, including labor, to rise, meaning that every component of building a house is more expensive than it used to be, he said. Demand for houses is also still outpacing supply, Izard said. “Right now, the U.S. is really short on houses, so regardless of what lumber’s doing, just the sheer amount of demand is really driving up the prices of houses,” he said. The median sales price of a home in April was $450,600, compared with the median sales price in April 2020 of $309,900, according to the U.S. Census Bureau. On average, housing materials in general have gone up about 20% year-over-year, Quercia said. “Furnishing, appliances, everything you can think of in a home is more expensive,” he said. The consumer price index increased 8.5% for the year ending in March, representing the largest 12-month increase since December 1981, according to the Bureau of Labor Statistics. And though prices are up, sales of homes are slowing because it’s difficult for homeowners selling their homes to find a new house to move into, Izard said. Will things ever get back to Normal?Experts say lumber prices will drop even more as soon as August when U.S. tariffs on Canadian softwood will be reduced, Quercia said. Duties on shipments of Canadian lumber to the U.S. will go from 17.99% to 11.64%, according to the National Association of Home Builders. “Reducing these tariffs is an important step forward to addressing America’s growing housing affordability crisis and easing extreme price swings in the lumber market that have added more than $18,600 to the price of a new home since late summer,” the association said in a statement. Newsom said from a strictly lumber standpoint, building now or a few months from now could be a good idea. But he advised anyone who is able to wait to start their projects to hold off until prices in general trend back down. “If they want to lock in their lumber prices now, it’s better than what it would’ve been before,” he said. “But (the price of) a house as a whole — I would probably hold off and wait for inflation in general to come down.” Experts say that as demand continues to slow and the global economy bounces back from disruptions caused by the COVID-19 pandemic, prices will start to stabilize. “There are signs that eventually the market will go back to normal,” Quercia said. “We’re looking at 2025.” But some developers and homeowners may not want to wait three years to start their projects. Embroidered North Face JacketsNorth Face jacket inventory is building up again as distributors around the country. The pandemic stopped production and halted the importing of the jackets for over 16 months. The question is how to price the jackets with custom embroidery and still be competitive in the market place with increasing inflation monthly. How to price your embroidery onto North Face and remain competitiveTraditional pricing models take the garment cost, double it, and add the embroidery costs work great in small-sized embroidery orders under 12 jackets. With more oversized-sized orders of 48 plus jackets, the pricing will become too expensive for that quantity. An example is taking 50 North Face jackets to cost $100.00 blank. Doubling the cost to $100.00, the profit per jacket is $100.00 * 50 jackets. $5,000 to embroider 50 jackets sounds like a significant profit margin but will also be too much of a cost to be competitive. A contract embroidery company would charge an embroidery broker $5.00 per logo. So, the broker has a $45.00 per jacket profit for not touching the work. The broker will then look at this situation and decide they only need to make $1,000 on this job and add $20.00 per jacket to make $1,000.00. Not an insufficient margin for processing paperwork. Use tiered costs when pricing North FaceThe tiered cost will need to be used, which has different margins based on the cost of the item. A $100.00 North Face will be calculated at a 25% margin plus embroidery vs. doubling costs like traditional shops already do. It understands some SQL CASE Statements to get a complete price list is necessary. We use a program called CASPIO, an online SQL database that is user-friendly with drag and drop fields and SQL statements that a non-computer user can understand. Caspio can price the entire Sanmar database and post it online. For further info on pricing or learning Caspio, please contact Erik Mickelson at [email protected]

We wish Kanha a Happy BirthdayKanha is an embroidery machine operator at Northwest Custom Apparel. June is her birthday month and the staff, customers and the community would like to wish Kanha a "Happy Birthday". We don't reveal a person's age however we do post some events that happened in Kanha's birth year. Event's in Kanha's birth year

Kanha inspires the staff at NW Custom ApparelWork got you stressed? Hit the gym 3 times per weekRunning an embroidery shop can put stress on you mentally and physically. Do you feel like Mack truck truck you over when 5:00 rolls around? Stress isn't good a person trying to run a small business and it reduces your performance workwise. You need to take time out for yourself and exercise 3 times per week. Picking the right gym for youThe exercise craze is huge after coming out of the pandemic lockdown. People on average put on 12-15 pounds of extra weight during the lockdown when gyms were closed for safety precautions.

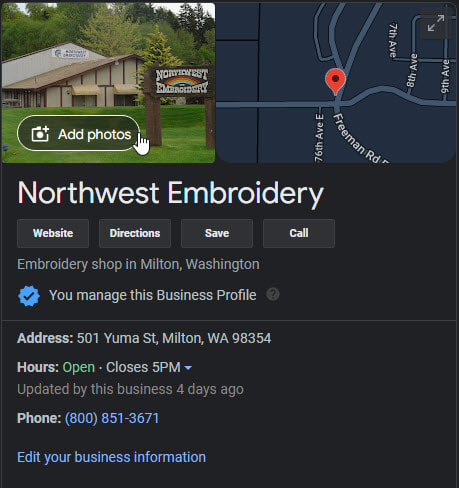

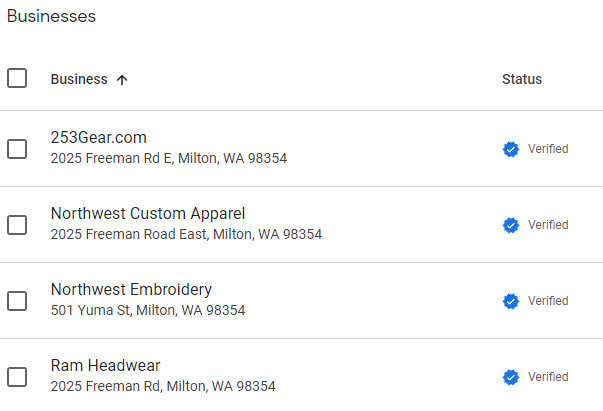

Update your Google Business Profiles regularly to get listed for local searchI try to update our Google business profiles with new content at least weekly. If you embroidery shop doesn't have a google business profile you need to create one so your company can start getting listed in the google engine. How many Google profiles? We have 4 business profiles for our other subset businesses connected to Northwest Embroidery. The more local companies you can list the better chance you have becoming ranked with Google. I update three additional business profiles; Northwest Custom Apparel, Ram Headwear and our retail t-shirt site, 253gear.com. What should I updateThey key is consistent posting, not necessarily worrying too much about what you want to say. I suggest starting with an update such as an employee's birthday, new product or a new customer. Remember customers love to have their name shouted out on the internet. Post lots of photosPotential customers love to see photos of your embroidery shop. Post photos of your embroidery, machines and employees. Today with mobile phones you should have no problem taking a high resolution photo with good lighting and clarity. When should you start posting?The worst post ideas is the one that sits in your head and not out into google land. It doesn't matter the quality when you start out, you just have to get one post started. You will get better weekly and in 45 days you will be a posting like a professional. Get out and start posting and watch your phones start ringing.

|

Categories

All

Archives

June 2023

AuthorErik Mickelson ,the Operations Manager since 1996 is a 2nd generation embroider. Erik started fulltime in his family's company after is graduation from Washington State University in 1996. |