|

Our Staff Is Huge Fans of Matt's Off-Road Recovery on You tube When it comes to off-road recovery, Matt’s Off Road Recovery is the leader in the industry. With its comprehensive services and experienced staff, they offer top-notch solutions for anyone who needs help getting their vehicle back on the road. Now, Northwest Embroidery wants to join forces with Matt’s Off Road Recovery as their official t-shirt vendor. Northwest Embroidery is a family-run business that has been in operation for over 45 years. They specialize in custom embroidery and screen printing for businesses and individuals alike. With their extensive experience and high quality products, they are confident that they can provide an excellent service to Matt’s Off Road Recovery by creating one of a kind t-shirts that will help spread awareness about the company. For those unfamiliar with Matt’s Off Road Recovery, it is an organization dedicated to providing assistance to anyone who finds themselves stuck or stranded while out on the trails. From simple tows to complex extractions, they provide a wide range of services that are tailored to each individual customer’s needs. By partnering with Northwest Embroidery as their t-shirt vendor, Matt’s Off Road Recovery can further cement their position as a leader in the off road recovery industry. Northwest Embroidery Loves Matt's Off Road Recovery T-Shirts Northwest Embroidery wants to be the official t-shirt and hoodie vendor for Matt's Off Road Recovery apparel. We specialize in creating high quality, comfortable clothing that celebrates the spirit of off road recovery. Our team of talented designers have worked closely with Matt's Off Road Recovery to create a unique line of shirts, hoodies, and caps that both look amazing and provide great comfort. The t-shirts feature an iconic design that captures the essence of off roading. The colors are vibrant and eye-catching, sure to make a statement wherever you go. The hoodies are made from premium materials and feature a modern cut that looks great on all body types. The caps come in several different styles and colors, so you can find the perfect one for your outdoor adventures. Northwest Embroidery is committed to delivering quality products that represent Matt's Off Road Recovery in a way that is both stylish and practical. We strive to provide excellent customer service while offering our customers unique designs at competitive prices. So if you're looking for a way to show your love for off road recovery, there's no better option than Matt's Off Road Recovery apparel from Northwest Embroidery. Northwest Embroidery Likes Matt's Off Road Recovery Caps At Northwest Embroidery, we're really excited about Matt's Off Road Recovery! Not only do we love their t-shirts, but now we can offer customers another great option: their caps. Our team takes pride in being able to provide customers with a wide range of products from Matt's Off Road Recovery. We know that our customers appreciate the quality of Matt's Off Road Recovery items. Their caps are no exception—they're made with excellent materials and feature vibrant colors that are sure to make a statement. Plus, they come in lots of different styles so customers can find the perfect one for them. No matter what type of off road recovery item you're looking for, Northwest Embroidery has you covered. We want to be part of the Matt's Off Road Recovery family and look forward to helping you find the perfect cap or t-shirt to show your support. Northwest Embroidery Want's To Be Matt's Off Road Apparel Supplier Matt's Off Road Recovery is a company that needs a reliable apparel supplier. Northwest Embroidery would like to be that vendor and provide their services. They believe they have the capacity and expertise to meet Matt's requirements in terms of quality, price, and turnaround time. Northwest Embroidery specializes in custom t-shirts, hats, and other apparel, making them a great choice for all of Matt's needs. Their team is experienced in creating unique designs that will help promote Matt's brand and make sure customers recognize it. Plus, they offer competitive pricing and quick turnaround times, so Matt can rest assured his order will be fulfilled quickly and accurately. In short, Northwest Embroidery has the perfect solution for Matt's Off Road Recovery when it comes to apparel production. Their experience with custom designs, competitive pricing structure, and fast turnaround times make them an ideal choice to be Matt's official apparel supplier. The Northwest Staff Loves Watching Matt's Off Road Recovery At Northwest Embroidery, we love watching Matt's Off Road Recovery. It's a unique and thrilling show that captures all the excitement and danger of off-road recovery. We've been captivated by the daring stunts and amazing recoveries made by Matt and his team. We particularly admire the skill and expertise they bring to each recovery job. The way they plan and execute each rescue is an inspiration to us all. They have mastered the art of off-road recovery and it shows! We'd be honored to become Matt's official apparel supplier, so that everyone can share in our admiration for this incredible show. Our high-quality products are perfect for any off-road enthusiast, and we'd be proud to contribute our part in supporting Matt's Off Road Recovery. Conclusion In conclusion, Northwest Embroidery would love to be Matt's Off Road Recovery T-shirt vendor. Everyone at Northwest Embroidery is passionate about the sport and loves watching Matt's Off Road Recovery adventures. Not only do they want to provide t-shirts, they are interested in providing caps and other apparel as well. With their expertise in creating quality products, Northwest Embroidery could provide a great service for Matt's Off Road Recovery fans. This would allow them to show off their pride and support for their favorite off road recovery team. Northwest Embroidery looks forward to hearing from Matt’s Off Road Recovery and hopes to become their go-to supplier for all of their apparel needs. Call us Matt We want to be your t-shirt supplierMatt and Ed, we can help you with Golden Nugget swag. T-shirts, hats and bags. You need cool bags for your Matt Straps. Call us 253-922-5793.. WE are big fans up here in Seattle

0 Comments

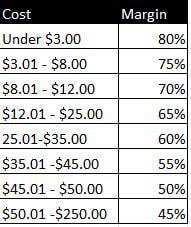

Embroidery is an art form that has been popular in Massachusetts since the 1600s. Even today, it continues to be a beloved craft and creative outlet for many people across the Bay State. In fact, according to The Embroiderers' Guild of America, Massachusetts currently ranks as one of the top five states with the most registered members! This reveals the immense appreciation held by locals for this timeless craft. But why do so many people love embroidery? From its unique history to its versatility in modern applications, there are plenty of reasons why we can’t get enough of this old-fashioned skill. To explore these further and uncover what makes embroidery such a cherished activity, let's take a look at 5 Reasons Why We Love Embroidery in Massachusetts. From colorful wall hangings to intricately detailed patches and pins, embroidered items have become increasingly popular over recent years - becoming more than just a hobby but instead an exciting way to express creativity through vibrant designs. Whether you're new to needlework or simply curious about all things related to embroidery, read on as we dive into some compelling facts behind this captivating craft and discover why it remains such an integral part of life here in Massachusetts! ## 1. History Of Embroidery In Massachusetts Why has embroidery become such a beloved craft in Massachusetts? With its centuries of history and remarkable artistry, it's no wonder that this traditional textile art is still going strong today. Embroidery in the Bay State dates back to colonial times when colonists used homespun fabrics and threads from local sheep flocks. Women often created intricate designs with motifs like flowers and animals for clothing, home décor, bedding, and quilts. This incredible skill was passed down throughout generations, ensuring that its legacy lived on despite wars or societal changes. It wasn't until the 1980s that needlework shops began appearing around the state, allowing more people access to supplies and instruction which eventually led to an explosion in popularity. Today, many schools across Massachusetts offer classes dedicated to learning different types of embroidery stitches while some towns even host their own annual festivals celebrating the craft! There are countless books filled with patterns and techniques as well as online resources offering tutorials so anyone can learn how to stitch beautiful pieces. In addition to being able to make gorgeous works of art, embroidery continues to be admired by many because it honors our shared past as well as current culture — proving that time-honored traditions never go out of style. ## 2. Artistry Of Embroidery It's no secret that embroidery is a timeless art form. For centuries, it has been used to create beautiful pieces of work and express creativity like nothing else can. Even in modern times, the ancient craft of embroidery continues to bring people together from all walks of life - especially here in Massachusetts! When you look at an embroidered piece, you can't help but be amazed by its beauty and complexity. From the intricate stitches to the unique designs, each piece is truly one-of-a-kind. The level of detail and skill required for creating these works of art make them even more impressive. Plus, there are several different types of embroidery techniques out there - so whether you prefer hand stitching or machine embroidering, you're sure to find something that suits your style. Embroidery also offers an incredible range of possibilities when it comes to telling stories through artwork. By combining color palettes, textures and patterns with thoughtful imagery, wearers can create meaningful statements about themselves – or their community – on whatever fabric they choose. Here's how: * Color Palette: A carefully selected combination of colors sets the mood for any design; warm tones evoke feelings happiness while cooler hues convey a sense of calmness. * Textures & Patterns: Combining various fabrics creates texture which adds depth and complexity to any project; incorporating subtle details such as stripes or polka dots further enhances this effect. * Imagery: Incorporating iconic images such as state flags or other symbols relevant to the wearer’s identity gives meaning beyond words alone - making it personal and special. By using these elements together in creative ways, the final product becomes much more than just cloth adorned with thread - it becomes a powerful representation of who we are as individuals and communities alike. And because each piece is unique in its own way, wearing embroidered clothing always stands out from the crowd! ## 3. Uniquely Massachusetts Embroidery Designs The skillful craftsmanship of embroidery in Massachusetts is truly something to behold. From intricate designs inspired by the local culture and history, to vivid colors that bring a modern twist on traditional styles, each piece made in the Bay State has its own unique charm. Here are some reasons why we love embroidery in Massachusetts: * Rich cultural heritage – Embroidered pieces often feature images or symbols from Native American tribes, representing their connection to the land and honoring their traditions. * Colorful and bold – Whether it’s bright florals or geometric patterns, Massachusetts-made embroidery always stands out with vibrant colors and interesting designs. * Creative flair – Local artisans use various elements such as beads and sequins to add texture and depth to their work - making for one-of-a-kind works of art. * Quality materials – The quality of fabrics used for embroidery projects is often high, ensuring years of wear when cared for properly. Embroidery in Massachusetts brings together two worlds - creativity and tradition - into one beautifully crafted piece. It's no wonder why so many people love wearing these creations! ## 4. Skillful Craftsmanship Of Embroidery In Massachusetts Massachusetts embroidery is renowned for its skillful craftsmanship. It takes patience, attention to detail and a creative eye to make the intricate designs that are so popular here in Massachusetts. Let’s take a look at why we love the craft of embroidery in this state: • The artistry: Embroiderers use their own unique creativity when they create pieces with vibrant colors, shapes and patterns. o Imagination – From landscapes to abstract works of art, each design tells an individual story through its imagery. o Precision – Each stitch must be exacting in order to achieve the desired result. • The tradition: Embroidery has been practiced by generations of artisans in Massachusetts for centuries. o Legacy – Experienced crafters pass down their skills and knowledge from one generation to the next. o Culture – Artwork reflects local customs and values, allowing us to appreciate our heritage through these timeless creations. Embroidery celebrates local culture while providing us with beautiful handmade works of art that will last for years to come. By appreciating skilled craftsmanship in Massachusetts, we can honor both old traditions and new ideas as we continue celebrating our culture through embroidery. ## 5. Celebrating Local Culture Through Embroidery The fifth reason why we love embroidery in Massachusetts is celebrating local culture through this art form. From traditional indigenous designs to modern-day motifs, the craftsmanship of Masschusetts' embroiderers reflects its cultural diversity and makes it a vibrant place for art. For instance, one can find exquisite hand sewn items such as: * Traditional Indigenous Designs: - Wampanoag Nation beadwork - Narragansett textiles with intricate weaving patterns * Modern Day Motifs: - Maine lobster applique designs on clothing items - Boston skyline patchworks stitched onto hats or bags. Embroidery has become an integral part of the fabric of Massachussets' culture and identity. It's not only a way to express our creativity but also serves as a reminder of how much we value preserving our heritage and traditions. As we continue to celebrate the skillful craftsmanship of Massachuetts' embroiderers, let us recognize their contribution to preserving our history and culture by supporting them whenever possible. With that said, let's take a look at how embroidery helps preserve hertiage in Massachusetts. ## 6. Preserving Heritage Through Embroidery It's easy to see why embroidery is loved in Massachusetts. From its vibrant colors, intricate designs and historical significance, there is so much that the craft has to offer. But have you ever stopped to consider how it can be used as an important tool for preserving heritage? Embroidery not only captures tradition and history within a piece of fabric or clothing, but also serves as a tribute to those who came before us. By stitching together vivid images, symbols and words we are able to create something timeless - something that pays homage to our ancestors' lives, cultures and stories. Embroidery offers an opportunity to bridge the past with the present and honor the people whose experiences shaped our society today. It's like having one foot firmly planted in yesterday while keeping another step ahead towards tomorrow. The unique skill of embroidering allows us to tell meaningful stories and share special memories with future generations. Not only does this practice keep these tales alive, but it also helps connect us all by creating tangible links between different family members or communities across time. Whether through traditional patterns or modern-day motifs, embroidered items are truly priceless keepsakes brimming with sentimentality and meaning - perfect for meaningful gift giving! ## 7. Meaningful Gift Giving With Embroidery Embroidery is a great way to show someone you care, and in Massachusetts it has been part of the culture for generations. Not only does embroidery look beautiful and capture memories, but it also provides meaningful gift giving opportunities. Here are just three reasons why: First, custom pieces can be tailored towards an individual’s interests or style, making them feel extra special on their big day. Second, there’s something about receiving a handmade piece that adds sentimental value to any celebration. Finally, these works of art often become lasting keepsakes with stories shared from generation to generation. Gifting embroidered items not only brings joy to friends and family members, but also helps support local businesses. Artisans who design and create these masterpieces rely on customers like us to keep their craft alive - which makes buying from small shops even more important! ## 8. Supporting Local Businesses Through Embroidery Embroidery is like a bridge, connecting people around Massachusetts and beyond. It offers an opportunity to reach out to those in need of support, be it through gift-giving or helping local businesses stay afloat. It’s easy to love embroidery for its ability to bring communities closer together. Every stitch that's sewn into fabric carries the potential for meaningful connections between individuals and organizations. This makes affording gifts easier on both the giver and receiver, as well as supporting small businesses during a time when they might otherwise struggle financially. By buying from these stores or customizing your own pieces with their help, you're doing your part to keep them from going under while also creating something unique and special for yourself or someone else. The act of threading needlework not only supports local shops but strengthens relationships too – whether it’s keeping traditions alive, celebrating special occasions such as weddings or birthdays, or simply showing appreciation - this type of craftsmanship connects us all together more deeply than ever before. ## 9. Connecting People Through Embroidery It's no secret that embroidery has become a popular pastime in Massachusetts. According to the Embroiderers' Guild of America, an estimated 2 million people throughout the country are actively engaged in needlework projects every year. Connecting people through embroidery is one of the most powerful reasons why we love it here: First, there’s the sense of community and collaboration it provides. By teaching each other new stitches and techniques, individuals can come together to create something meaningful. Second, there’s the joy of creating beautiful artwork from raw materials like thread and fabric. Third, there’s the connection between generations as many designs have been passed down for centuries. Finally, there’s its ability to help us express our creativity without worrying about perfection or being judged by others around us. Embroidery encourages self-expression and puts more focus on learning than what results you get at the end — making it even more special when your project does turn out well! As a result, this art form continues to bring communities closer together while also helping us explore our own imaginations. ## 10. Popularity Of Embroidery In Massachusetts Embroidery in Massachusetts is like a beacon of light, shining brightly and radiating joy. It has become increasingly popular over the years as a creative outlet for those who love to stitch. From their own homes, people are creating intricate pieces that bring beauty into the world. Massachusetts has experienced an explosion of enthusiasm for embroidery recently. Many towns have special clubs and meetups dedicated to the craft, where members can show off their work and learn new techniques from one another. Embroidery classes are also popping up all across the state, allowing anyone with an interest in stitching to practice it without having to purchase expensive equipment or materials. The community spirit surrounding this art form has been growing steadily, which is why more and more people are turning to it as a source of comfort and connection during difficult times. ## Conclusion Embroidery in Massachusetts is a rich tradition that has been around for centuries. From its history to the skillful craftsmanship of handmade pieces, it’s no surprise that embroidery remains popular in the Bay State today. In fact, according to recent surveys from the American Needlepoint Guild (ANG), more than 60% of Massachusetts residents have participated in some type of embroidery activity within the past year. This statistic shows just how popular and beloved this unique art form is among locals! Whether you are looking for a meaningful gift or simply want to celebrate local culture, embroidering offers something special for everyone. Not only does it provide an opportunity to connect with friends and family through creative expression, but also helps support small businesses throughout the state. Embroidered items can be found everywhere from online shops to street fairs, so there's no shortage of options when it comes to creating something truly beautiful and one-of-a-kind. For those who love both crafting and supporting their community, embroidery in Massachusetts is a great way to do both at once. With its deep roots in history, vibrant designs, and skilled crafters - we will continue to see why people across the Commonwealth embrace this timeless artform each day. According to industry statistics, in 2022, there will be over 3 million construction companies in the U.S. With such market saturation, making sure your construction company stands out from the competition has never been more critical. Business owners can grow their construction company by handing out t-shirts and caps to help promote their company. Your construction business caps and t-shirts should be high quality with a crisp, bold logo that's seen from 25 feet away. Your t-shirts should have a left chest print and a full back print that displays your logo and slogan in bold letters. Marketing is valuable, meaning a construction company shirt is only as effective as the branding it displays. Analyzing how effectively your logo and slogan communicate your construction company's purpose and identity can help to look at different companies that have mastered it. Before we get started, check out some t-shirts Northwest Custom Apparel has printed for construction companies like yours. Roofing Contractors use Embroidered Caps and Screen Printed ShirtsT-Stone Construction uses Safety Shirts and VestsTaylor Metal Products brands with Richardson 112 Embroidered CapsMyler Construction uses Custom Coffee Mugs to highlight their brandErik Mickelson is the Blog Author at Northwest Custom ApparelThe Making of the Apparel Graphic Industry |

AuthorErik Mickelson is a contributing co-author for Northwest Custom Apparel and has over 25 years in the embroidery industry. Questions on how to start an embroidery company, please reach out to Erik at [email protected] |

Northwest Custom Apparel

Little Known History of Carhartt Jackets

The 1890s were booming for Carhartt, with the Trans Northern Railroad laying track only 2 miles from Carhartt's original manufacturing site. The site was perfect for Carhartt to sell jackets to the railway workers. Plus, being so close to the rail tracks, he could ship his jackets to the West Coast. Carhartt's expansion grew to 8 facilities around the country and continued growing until the Great Depression hit.

The railroad opens up the West for Carhartt

Carhartt in the Great Depression

World War II and Carhartt

Carhartt Custom Embroidery

The completion of the Alaskan Pipeline in 1977

The completion of the Alaskan Pipeline in 1977 Carhartt in the 2020s and beyond

Author

Erik Mickelson is a 2nd generation embroider and has been in the industry since 1997. Northwest Custom Apparel is a supplier of Embroidered Carhartt Jackets, t-shirts and caps.

Carhartt embroidery is a necessity for my HVAC employees during service calls to identify our company and address any safety concerns.

Factory Tour, Embroidery, Thread, Caps, and Showroom.

Embroidery Machines

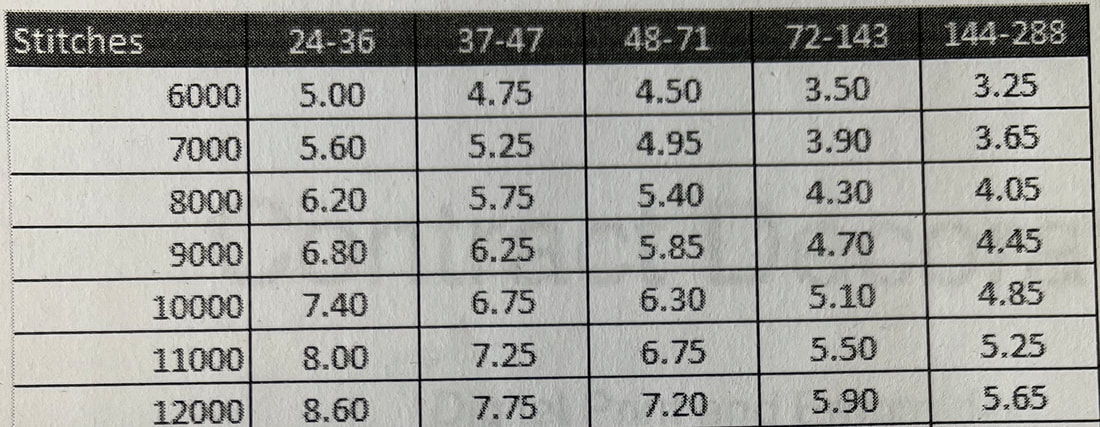

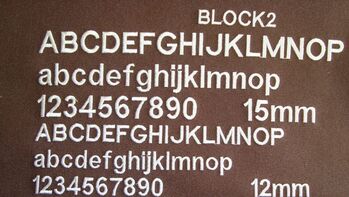

The Japanese company, Tajima, manufactured our embroidery machines, and we have used this brand for nearly 40 years. The embroidery machines hold up to 10 different thread colors, giving you a pleasant color palette to make your design pop. The speed of the embroidery machines, on average, runs at about 550 stitches per minute to ensure quality and productivity. We ran the machines at nearly 900 stitches per minute, and they still produced crisp embroidery. The embroidery machine you see in the video is stitching polo shirts and fleece pullovers that are excellent choices for outfitting your employees.

Cap Embroidery

Showroom Tour

Notable Customers

Production Crew hits 20,000 caps embroidered.

What's the next "Embroidery Adventure"?

Author

Erik Mickelson is a 2nd generation embroider, with over 25 years in the embroidery industry.

Embroidery is the bond between employees and their boss"

Categories

All

Alaska

Caps

Community

Contract Embroidery

Embroidery

Embroidery Adventures

Employees

Gift Giving Ideas

Google Marketing

History NW Embroidery

Kornit

Local News

Oregon

Patches

Polo Shirts

Pricing Tips

Promotional Products

Safety Shirts

Screen Printing

Tradeshows

T Shirt Marketing

T-Shirt Marketing

Webstores

Archives

June 2023

May 2023

February 2023

December 2022

October 2022

September 2022

August 2022

July 2022

June 2022

April 2022

February 2022

Author

Erik Mickelson ,the Operations Manager since 1996 is a 2nd generation embroider. Erik started fulltime in his family's company after is graduation from Washington State University in 1996.