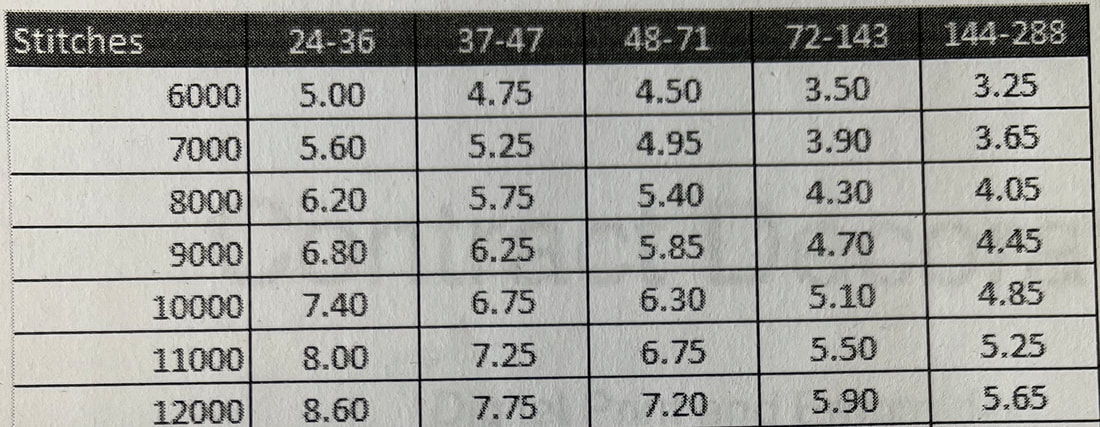

Embroidery benefits customers and operators The benefits of embroidery are that it gives an elegant finish and screams quality when stitching a company's logo. Embroidery operators find personal satisfaction while stitching a clean, crisp logo and seeing the customer smile. Embroidery operators must possess hand-eye coordination to take a thread and insert it through the embroidery needle. Our operators find stitching healing and allow them to relax and get their minds off of everyday stress. Operators have also mentioned it builds confidence, improves eyesight, and reduces anxiety. What can be embroidered? Embroidery is applied with a needle and thread, limiting the design's small detail. Owner Jim Mickelson says, "If you can draw it with a Sharpie felt tip pen, we can embroider it." The left chest logo position is the most popular embroidery location. It is on the left chest because when shaking hands with a customer, they will be able to read your logo. The left chest design is usually 2" tall and 4" wide, making it able to be viewed from 3 to 5 feet away. Embroidery isn't the best option for items you can't frame a circular embroidery hoop. Troublesome embroidery items include backpacks with zippers, polo shirts with a pocket, jackets with seams running down the back, and any lightweight fabric, making securing a stitch impossible. How does embroidery pricing work? Embroidery's pricing unit is based on the "stitch count" in a design. Generally, an embroidery machine can stitch 550 stitches per minute. Multi-head embroidery machines can have different heads, from one to 12 sewing heads, making larger embroidery machines more efficient and pricing lower. A typical left chest embroidery logo has 8,000 stitches and 3 thread colors and is the optimal design for an embroidery machine to be productive. Pricing embroidery is based on the number of stitches, machine speed, labor rate, and factory overhead. For example, if you know your factory rate is $100.00 per hour, use an 8-head embroidery machine and can produce 16 logos per hour. The calculation would be $100.00/16 = $6.25 per logo. I also suggest taking the worst-case production rate and dividing it into the factory costs, so you can factor in the operator's bathroom breaks, inefficiencies, and machine problems. To be safe on the above calculation, I would say the hourly rate is 12 units, which would increase the cost to $8.33 per logo What should I charge for monogramming shirts? |

AuthorErik Mickelson is a contributing co-author for Northwest Custom Apparel and has over 25 years in the embroidery industry. Questions on how to start an embroidery company, please reach out to Erik at [email protected] |

Northwest Custom Apparel

Thank you for pointing out that utilizing embroidery to monogram clothing takes a long time because you can only do one personalized name at a time. My sister wants to make shirts for her employees. I'll advise her to get custom embroidery done so that she can save time by not having to do it herself.

It's interesting to know that choosing a thread supplier that has been in the industry for many years is in the country when choosing a thread type. I can imagine how doing that can ensure that the embroidery services we will be getting will finish on time. We need their help to create some pieces as souvenirs for our wedding day in March next year, so I hope to find one with the best materials as well.

Wilcom is worth its price with the increase in productivity and the quality of stitching and is a must-have for a beginner embroider. I truly appreciate your great post!

Leave a Reply.

Categories

All

Alaska

Caps

Community

Contract Embroidery

Embroidery

Embroidery Adventures

Employees

Gift Giving Ideas

Google Marketing

History NW Embroidery

Kornit

Local News

Oregon

Patches

Polo Shirts

Pricing Tips

Promotional Products

Safety Shirts

Screen Printing

Tradeshows

T Shirt Marketing

T-Shirt Marketing

Webstores

Archives

June 2023

May 2023

February 2023

December 2022

October 2022

September 2022

August 2022

July 2022

June 2022

April 2022

February 2022

Author

Erik Mickelson ,the Operations Manager since 1996 is a 2nd generation embroider. Erik started fulltime in his family's company after is graduation from Washington State University in 1996.