The day has finally come, and your all-star Kornit operator walks into your office and gives you his two-week notice. You are speechless as your stomach turns and your forehead sweats; what will you do now? I know this feeling since it has happened to me just in the past and just recently. Here are some suggestions on what to do when your operator quits. All the Kornit Information is in the Operators Head  Kornit printers are glitchy, and trying to write a complete manual on all the little problems would turn into a 500-page novel. There is no way to cover every Kornit operating hiccup. The scary thing is all this knowledge is stuck in the operator's head and not documented anywhere. Once the all-star person leaves, you start over from scratch like a company that has never used a Kornit before. Have the printer operator train you |

AuthorErik Mickelson is a contributing co-author for Northwest Custom Apparel and has over 25 years in the embroidery industry. Questions on how to start an embroidery company, please reach out to Erik at [email protected] |

Northwest Custom Apparel

Little Known History of Carhartt Jackets

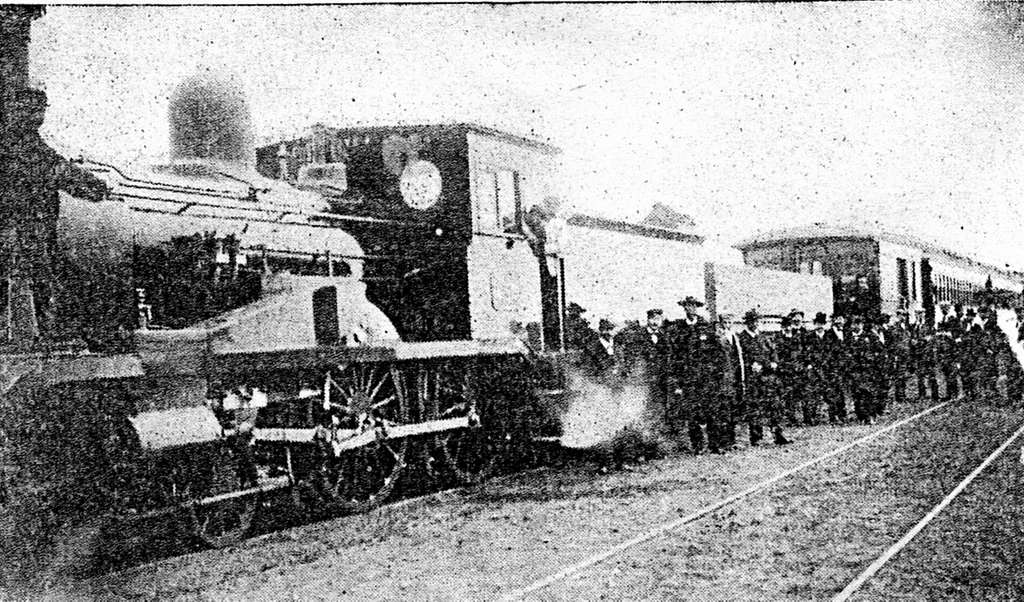

The 1890s were booming for Carhartt, with the Trans Northern Railroad laying track only 2 miles from Carhartt's original manufacturing site. The site was perfect for Carhartt to sell jackets to the railway workers. Plus, being so close to the rail tracks, he could ship his jackets to the West Coast. Carhartt's expansion grew to 8 facilities around the country and continued growing until the Great Depression hit.

The railroad opens up the West for Carhartt

Carhartt in the Great Depression

World War II and Carhartt

Carhartt Custom Embroidery

The completion of the Alaskan Pipeline in 1977

The completion of the Alaskan Pipeline in 1977 Carhartt in the 2020s and beyond

Author

Erik Mickelson is a 2nd generation embroider and has been in the industry since 1997. Northwest Custom Apparel is a supplier of Embroidered Carhartt Jackets, t-shirts and caps.

Carhartt embroidery is a necessity for my HVAC employees during service calls to identify our company and address any safety concerns.

Factory Tour, Embroidery, Thread, Caps, and Showroom.

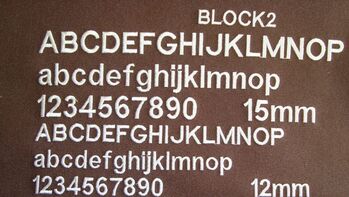

Embroidery Machines

The Japanese company, Tajima, manufactured our embroidery machines, and we have used this brand for nearly 40 years. The embroidery machines hold up to 10 different thread colors, giving you a pleasant color palette to make your design pop. The speed of the embroidery machines, on average, runs at about 550 stitches per minute to ensure quality and productivity. We ran the machines at nearly 900 stitches per minute, and they still produced crisp embroidery. The embroidery machine you see in the video is stitching polo shirts and fleece pullovers that are excellent choices for outfitting your employees.

Cap Embroidery

Showroom Tour

Notable Customers

Production Crew hits 20,000 caps embroidered.

What's the next "Embroidery Adventure"?

Author

Erik Mickelson is a 2nd generation embroider, with over 25 years in the embroidery industry.

Embroidery is the bond between employees and their boss"

We want to highlight some of the recent nominations that come through for the week of July 4th to 10th, 2022.

Boo is a lot sweet and goofy with a bit of sass. Loves: His girl (my daughter), rolling in the dirt, scratches, treats, jumping. Dislikes: Other horses/ponies, water, fireworks Name Meaning: Boo got his name because his birthday is Halloween. Fun Fact: Boo looks like a different pony from winter to summer. He grows a really thick, furry, dark coat in the winter. After he sheds (a lot!), his coat becomes sleek with reddish tones and adorable dapples in the summer.

Charlotte is the sweetest 1-eyed pirate dog that enjoys walks around the neighborhood, car rides, frolicking in the yard, and snuggling. She prefers to snuggle with a pillow, with a kid's stuffed animal, under the blankets. She is the very best!

Momo is a mischievous and playful little guy who's more intelligent than you're an average cat, but only when he wants to be. He knows how to shake for treats and is good at getting his owners out of bed at 3am for an early breakfast. They happily oblige, though, because it's hard to say no to his cute face and mannerisms.

How to Submit Your pets to Pet of the Month

It's a summer Friday at Northwest Custom Apparel, and we are filled to capacity with t-shirts, caps, and embroidered vests today. I decided to get out my GoPro and make a quick, fun video that flies through the factory, showing what we are doing today. In the first clip, Brian and Joe are printing t-shirts with our Kornit direct-to-garment printer. Brian says, "We are full to capacity, so stop selling orders!" Don't worry; they will be working overtime to put some extra money in their wallets. We really appreciate Brian and Joe for keeping the printers pumping out t-shirts. We do a GoPro fly by the t-shirts and sweatshirts the guys printed today.

Stitching Caps

Nai in our cap department is stitching some trucker caps with an Alaskan Lodge in a scarlet and snow-white thread. This trucker cap is one of our more popular caps, and Nai loves to embroider them.

Seattle Children's Hospital Embroidery

Theavy, our embroidery operator showing off an embroidered vest for the Seattle Children's Hospital. This is the same hospital Russell Wilson visited each Monday before being traded to the Denver Broncos.

I wanted to use my selfie stick to get a birds' eye view of the staff loading a new embroidery design into the computer. Our 8-head Tajima embroidery machine runs the Seattle Children's Hospital job that ordered 100 fleece pullovers and jackets for their nursing staff. My wife is a nurse and loves her pullovers from Cutter and Buck.

Thank you to our Awesome Staff

Antonio and Alicia are folding and preparing the completed shirts for shipment or customer pickup. Antonio has been a great help since he started last month. The kid's banner at the end of the video is from Little Giggles Daycare in Edgewood. If you remember, in our other Facebook videos of the daycare and the graduation t-shirts. This is the daycare we helped out with.

It's late Friday afternoon and about an hour before I head home, so I need to cut this blog short and start shutting up shop to enjoy a warm and sunny weekend.

See you guys next week, Erik

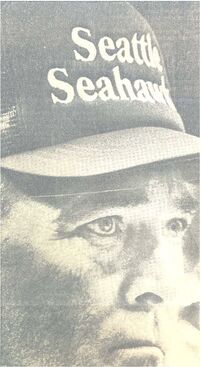

1 hat's off limits to Seahawk fans

P-I Reporter (1987)

Head Seahawk Coach, Chuck Knox wears his custom made cap from Northwest Embroidery

Head Seahawk Coach, Chuck Knox wears his custom made cap from Northwest Embroidery Some football fanatics will pay scalpers' prices to watch Sunday's American Conference championship game in the Los Angeles Coliseum, but the cap protecting the scalp of Seattle Coach Chuck Knox is not for

sale.

Not even for the $100 offered yesterday by one Seahawks caller.

Knox favors a simple, navy-blue baseball-type model with the words "Seattle Seahawks" printed in white across the front crown.

And while several different Seahawk hats are on general sale, you need good friends on the team, not money, to wear a cap like the coach's.

The hat was designed by Walt Loeffler, the Seahawks' equipment manager, who has turned down a number of offers to mass market it.

"I've been fighting it," says Loeffler. "I don't want 6.5,000 fans wearing the same hat worn by Coach Knox. I want it to be something a little special.

"I knew Knox liked hats. I didn't like the one our coaches used to wear (blue with a Seahawks logo patched on the front), so I designed this one," Loeffler said.

More than 92,000 tickets were printed for Sunday's game but Walt Loeffler, the Seahawks' equipment manager, ordered only just over 200 of these special Knox caps. Members of the coaching staff wear them.

One fan, an admirer of Knox's headgear, telephoned Seahawks headquarters yesterday and offered to pay $100 for the head coach's hat.

When told it wasn't for sale and that none is available for public purchase, the fan yelled "Go Hawks!" and hung up.

Three Seattle assistant coaches join Knox in wearing the cap during games. They are assistant head coach Tom Prohaska, offensive coordinator Tom Catlin and backfield coach Chick Harris.

There are five different styles of Seahawks caps available to the public. The most popular model for sale has a blue brim, a gray crown, and the team logo running along either side of the crown.

3,500 tickets gone

Meanwhile, only 150 tickets to Sunday's game against the Raiders at home in Los Angeles are still available in the Seattle area. They are at Doug Fox Travel, and they are expected to be gone later today.

Categories

All

Alaska

Caps

Community

Contract Embroidery

Embroidery

Embroidery Adventures

Employees

Gift Giving Ideas

Google Marketing

History NW Embroidery

Kornit

Local News

Oregon

Patches

Polo Shirts

Pricing Tips

Promotional Products

Safety Shirts

Screen Printing

Tradeshows

T Shirt Marketing

T-Shirt Marketing

Webstores

Archives

June 2023

May 2023

February 2023

December 2022

October 2022

September 2022

August 2022

July 2022

June 2022

April 2022

February 2022

Author

Erik Mickelson ,the Operations Manager since 1996 is a 2nd generation embroider. Erik started fulltime in his family's company after is graduation from Washington State University in 1996.