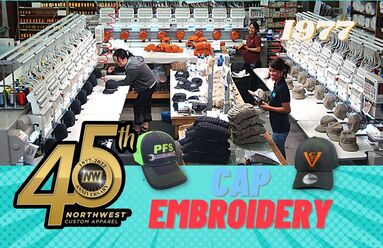

Factory Tour, Embroidery, Thread, Caps, and Showroom. In my inaugural episode of "Embroidery Adventures," I haven't laid out a roadmap to how I will create embroidery adventure videos to keep the audience entertained. I started by giving a factory tour of our embroidery and cap departments and ending with an overview of our showroom. I hope you enjoy the video and I would love to hear more comments about what you would like to see in upcoming "Embroidery Adventures". Stitching is in my blood and I am excited to share my embroidery adventure with you. You can reach me at [email protected] Embroidery MachinesOur embroidery factory has commercial, industrial machines that can stitch 8 items in synchronization, which allows us to keep the embroidery costs down. You can see why embroidering one thing is costly because you aren't utilizing the other 7 embroidery heads. The Japanese company, Tajima, manufactured our embroidery machines, and we have used this brand for nearly 40 years. The embroidery machines hold up to 10 different thread colors, giving you a pleasant color palette to make your design pop. The speed of the embroidery machines, on average, runs at about 550 stitches per minute to ensure quality and productivity. We ran the machines at nearly 900 stitches per minute, and they still produced crisp embroidery. The embroidery machine you see in the video is stitching polo shirts and fleece pullovers that are excellent choices for outfitting your employees. Cap Embroidery The difference between a baseball cap and garment embroidery is the frame used to mount the cap. The cap frame is circular, sits inside the cap, and then clicks into the embroidery machine. The machines are Tajima and can stitch 8 baseball caps at a time. Caps are a little trickier to get crisp embroidery due to the spherical layout of a cap crown. You are limited to the size of your embroidery logo to 4" wide by 2" tall. Anything more significant, the embroidery needle would strike the cap bill, causing damage to the cap and machine. Showroom TourAs you can see in the video, we have a fully stocked showroom with sample caps, promo items, workwear, t-shirts, polos, and much more. We specialize in workwear such as safety hoodies, vests, Carhartt jackets, and t-shirts. Notable CustomersThe video hits a panoramic shot featuring some of our notable customers over our 45-year history. The embroidered logos collages include football teams, fire departments, tribal, plumbing, Starbucks, and city and municipalities. Suppose you are familiar with the Discovery Channel and the show "Deadliest Catch." In that case, you will notice Captain Phil Harris and his son in front of our employee group photo. We stitched Phil's jackets for his boat, the Cornelia Marie. Production Crew hits 20,000 caps embroidered.On June 5th, 2008, our embroidery production crew hit a production record by stitching 20,000 caps within 7 days. This embroider feat hasn't been broken since then and may stay in the Northwest Custom Apparel record books for many more years. The order was for the release of Microsoft's "Halo" video game that year. Microsoft gave out a Halo cap to the first 20,000 customers who purchased the game. Our production manager at the time, Mongkon Ham, worked the crew for 12 hours per day, 7 days per week, to complete this order on time. What's the next "Embroidery Adventure"? In the following embroidery adventure, only time will tell what we will have in store for the audience. We are flying by the seat of our pants when creating these adventures. We would appreciate your comment and give us ideas on what you would like to see for the next adventure. I see embroidery daily and need your comments to keep the videos going. AuthorErik Mickelson is a 2nd generation embroider, with over 25 years in the embroidery industry. Embroidery is the bond between employees and their boss"

0 Comments

Leave a Reply. |

Categories

All

Archives

June 2023

AuthorErik Mickelson ,the Operations Manager since 1996 is a 2nd generation embroider. Erik started fulltime in his family's company after is graduation from Washington State University in 1996. |