|

When it comes to embroidery, no one does it better than Northwest Embroidery in Seattle. If you're looking for the best quality, selection, and service when it comes to custom embroidered clothing and accessories, Northwest Embroidery is the place to go. From their commitment to excellence in craftsmanship, to their unbeatable customer service, they have everything you need for your embroidery needs. In this article, we will explore why Northwest Embroidery is the best embroidery shop in Seattle.

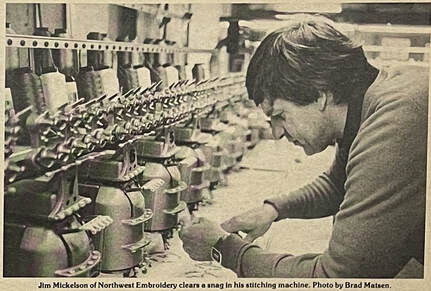

From the moment you walk into their store, you can tell that Northwest Embroidery takes pride in their work. They offer a wide selection of apparel and accessories that are perfect for any occasion or event - from t-shirts and hats to bags and jackets. Their knowledgeable staff is always willing to help find the best fit for your needs and provide advice on which options will look best for your project. Plus, they offer a variety of customization options so that your order can be customized just the way you want it. At Northwest Embroidery, they take customer satisfaction seriously and strive to provide top-notch quality with every order. They use high-quality materials and advanced technologies to ensure that each piece is crafted with precision and attention to detail. And with a satisfaction guarantee policy in place, customers can be sure they'll get exactly what they paid for or their money back - no questions asked! With all these features combined, there's no doubt that Northwest Embroidery stands out as one of the best embroidery shops in Seattle. What Is Northwest Embroidery? Northwest Embroidery is a unique local shop located in Seattle, Washington. It specializes in creating custom embroidered items like t-shirts, hats, jackets and more. With over 30 years of experience, Northwest Embroidery has established itself as one of the best embroidery shops in the city. The company's dedication to quality and customer satisfaction has made it a go-to destination for locals and visitors alike. At Northwest Embroidery, customers can choose from hundreds of colors and fonts to create their own unique design. They also offer digitizing services which allow customers to transform any artwork into a professionally-embroidered masterpiece. Moreover, their fast turnaround times make them one of the most reliable embroidery shops in the area. One thing that sets Northwest Embroidery apart from other shops is its commitment to using high-quality materials. All of their products are made with top-grade threads and fabrics that won't fade or fray over time. This ensures that customers will get a durable product that looks great for years to come. With competitive prices and excellent customer service, it's no surprise that Northwest Embroidery is considered the best embroidery shop in Seattle. Quality Of Products And Services When it comes to finding a reliable, quality embroidery shop in Seattle, Northwest Embroidery stands out. It's renowned for its top-notch products and services. Let's delve into the reasons why it's the best embroidery shop in town. First, Northwest Embroidery offers a wide range of custom-made products that are made with high-quality materials. Their experienced team creates items such as hats, jackets, bags, shirts and more with precision and attention to detail. Additionally, they also offer screen printing services to help customers create unique designs on their garments. With these options available, customers can be assured that they are getting quality products from Northwest Embroidery every time. Moreover, the customer service at Northwest Embroidery is second to none. The staff is always willing to go above and beyond to make sure that each customer has an enjoyable experience when shopping there. They are patient with questions and eager to accommodate any requests or special orders that customers may have. From product selection advice to designing ideas and delivery arrangements – you name it – the team at Northwest Embroidery will take care of it for you! Overall, Northwest Embroidery provides excellent quality products and exceptional customer service which makes them stand out from other embroidery shops in Seattle. With a wide range of options and attentive staff members ready to assist you with your needs, this is definitely the place to go if you're looking for quality embroidered items! Range Of Embroidery Options At Northwest Embroidery, there's no shortage of options when it comes to embroidery. From custom mugs and hats to t-shirts and blankets, they offer a wide variety of products that can be customized. Whether you're looking for a one-of-a-kind gift for someone special or a personalized item for yourself, Northwest Embroidery has something for everyone. They also specialize in corporate embroidery, making sure that businesses have the perfect logo apparel and promotional items to represent their brand. They have a team of experienced designers who can take any concept and turn it into reality with the highest quality materials. With this level of service, businesses can rest assured knowing their company will be well represented. At Northwest Embroidery, customers never have to worry about not getting exactly what they want. They provide excellent customer service and are always willing to go the extra mile to make sure every customer is satisfied with their product. From start to finish, they work closely with clients to ensure that every piece meets their expectations in terms of design and quality. No matter what type of embroidery you need, Northwest Embroidery provides top-notch services with an extensive selection at competitive prices. Their commitment to excellence has made them one of Seattle’s best embroidery shops – so if you’re looking for quality custom items with unique designs, you know where to go! Variety Of Threads Northwest Embroidery offers a wide variety of threads for all customers' needs. From rayon to polyester, there's something in stock for everyone. No matter the project or design, they have an option that will work perfectly. Whether you're creating a unique piece of clothing or decorating a piece of furniture, Northwest Embroidery has an array of threads for you to choose from. They carry different colours and weights so you can find the right one for your project. Plus, their knowledgeable staff are always on hand to help you decide which thread is best suited for your project. The quality of the threads at Northwest Embroidery is top-notch; it won't fray or unravel easily like cheaper alternatives tend to do. Their threads are also colourfast, so they won't fade or bleed over time. This ensures that your embroidered projects will last through many wears and uses. With all these features, it's easy to see why Northwest Embroidery is the best embroidery shop in Seattle. Their selection of threads is unbeatable and their knowledgeable staff make it easy to find what you need for any project. Whether you're just starting out with embroidery or have been doing it for years, Northwest Embroidery has everything you could need - from thread to advice! Affordable Prices When it comes to finding the best embroidery shop in Seattle, Northwest Embroidery is a top choice. One reason for this is their affordable prices. They offer custom designs at an accessible cost, making them a great option for anyone looking to get quality embroidery without breaking the bank. At Northwest Embroidery, customers can also find a variety of thread colors and textures. Whether you’re looking for something classic or more modern, there’s something for everyone at this shop. Plus, they have an experienced staff that can assist with design ideas and color selection. This ensures that you get the perfect piece of embroidered artwork every time! The affordability and variety of threads offered by Northwest Embroidery makes it easy to see why it’s one of the best embroidery shops in Seattle. With competitive prices and a wide selection of materials, they make customizing your project simple and enjoyable. There’s no better way to add a personal touch to your clothing or home decor than with beautiful embroidered pieces from this shop! Quick Turn-Around Times Turn-around time is a key factor when it comes to finding an embroidery shop. At Northwest Embroidery, they understand the importance of quickly delivering quality work. They focus on meeting their customers’ needs with quick and efficient turn-around times. No matter what project you need completed, Northwest Embroidery will strive to get it back to you in record time. Every order placed is treated as if it were the only one they have - meaning that it will be given top priority from start to finish. This allows them to provide fast and reliable service that other embroidery shops simply cannot match. Customer satisfaction is always their primary goal, and the team at Northwest Embroidery goes above and beyond to make sure this happens. With their commitment to quick turn-around times, customers can rest assured that their projects will be completed in a timely manner and meet all of their expectations. In addition, their affordability makes them an even more attractive option for those looking for great embroidery services without breaking the bank. At Northwest Embroidery, they understand that time is of the essence and are dedicated to providing quality services at lightning speeds. Whether you need something done right away or just want your project done quickly and professionally, they have got you covered! Wide Range Of Customization Options Northwest Embroidery has a wide range of customization options, so you can find something to fit your particular style. Whether you're looking for something simple and classic, or something more elaborate and modern - they've got it. From traditional monograms and crests to complex designs with multiple colors, there's no shortage of choices. And they'll help guide you through the process to make sure that the design matches your vision. But beyond just providing a range of styles and designs, Northwest Embroidery also offers custom orders for those who need something truly unique. They'll work with you to create an original piece that is tailored specifically for you. And since they do all their embroidery on-site, it guarantees a fast turnaround time without sacrificing quality. So if you're looking for high-quality embroidery with a variety of customization options in Seattle, look no further than Northwest Embroidery. With their attention to detail and commitment to customer satisfaction, they'll make sure your project comes out exactly how you want it - all while keeping your budget in mind. Friendly And Professional Staff At Northwest Embroidery, you can expect the highest level of customer service. The staff is friendly and professional, always ready to assist in whatever way possible. Whether you’re looking for a simple t-shirt or something more complex like a cap, the team is there to help you every step of the way. The staff has extensive knowledge on all types of embroidery and how it works. They can guide you through the customization process, helping you choose the right colors, fonts, and designs for your garment. They will also provide valuable advice on which materials are best suited for your project. This level of expertise makes Northwest Embroidery stand out from other shops in Seattle. You won't have to worry about getting lost in a bureaucracy here; the staff works hard to make sure that every customer's needs are met quickly and efficiently. From start to finish, they provide an excellent experience by offering helpful advice, answering questions promptly and delivering quality results. With such friendly and professional assistance, it's no wonder why Northwest Embroidery is one of the most trusted embroidery shops in Seattle. No matter what kind of project you have in mind, Northwest Embroidery will ensure that your expectations are exceeded with their helpful staff and wide range of customization options available. Satisfaction Guarantee At Northwest Embroidery, customer satisfaction is a top priority. That's why they offer a satisfaction guarantee. If customers aren't happy with the work they've received, Northwest Embroidery is willing to make it right. This guarantee speaks volumes about their dedication to providing the best service possible. The team members at Northwest Embroidery are highly experienced and knowledgeable when it comes to embroidery services. They're always happy to answer any questions customers may have and can provide expert advice on design ideas or how to choose the right thread color. Plus, they're friendly and personable, making sure customers feel comfortable and appreciated every step of the way. When choosing an embroidery shop in Seattle, Northwest Embroidery stands out from the rest for its commitment to customer satisfaction. Their satisfaction guarantee is just one more reason why so many people trust them for all their embroidery needs. With high-quality services and a friendly staff, Northwest Embroidery is truly the best option for anyone looking for exceptional embroidery services in Seattle. Convenient Location Located in the heart of Seattle, Northwest Embroidery is one of the best embroidery shops around. With a convenient location, it's easy to get to and find exactly what you need. Here's why it stands out among other local stores. Firstly, Northwest Embroidery is close to many other stores and restaurants in the area. This means that customers can access the shop quickly and easily, no matter where they are coming from. Furthermore, public transportation options are within walking distance so getting there isn't an issue either. Secondly, the store itself has a wide selection of products for customers to choose from. From apparel to accessories and everything in between, there's something for everyone here. The staff is also incredibly helpful when it comes to finding just what you're looking for - whether it be a special item or just something small that'll make your project pop! No matter what kind of embroidery you're looking for, Northwest Embroidery has got you covered. With its great selection of products and convenient location near downtown Seattle, it's no wonder why this shop is considered one of the best in town!

0 Comments

The Making of the Apparel Graphic Industry |

Categories

All

Archives

June 2023

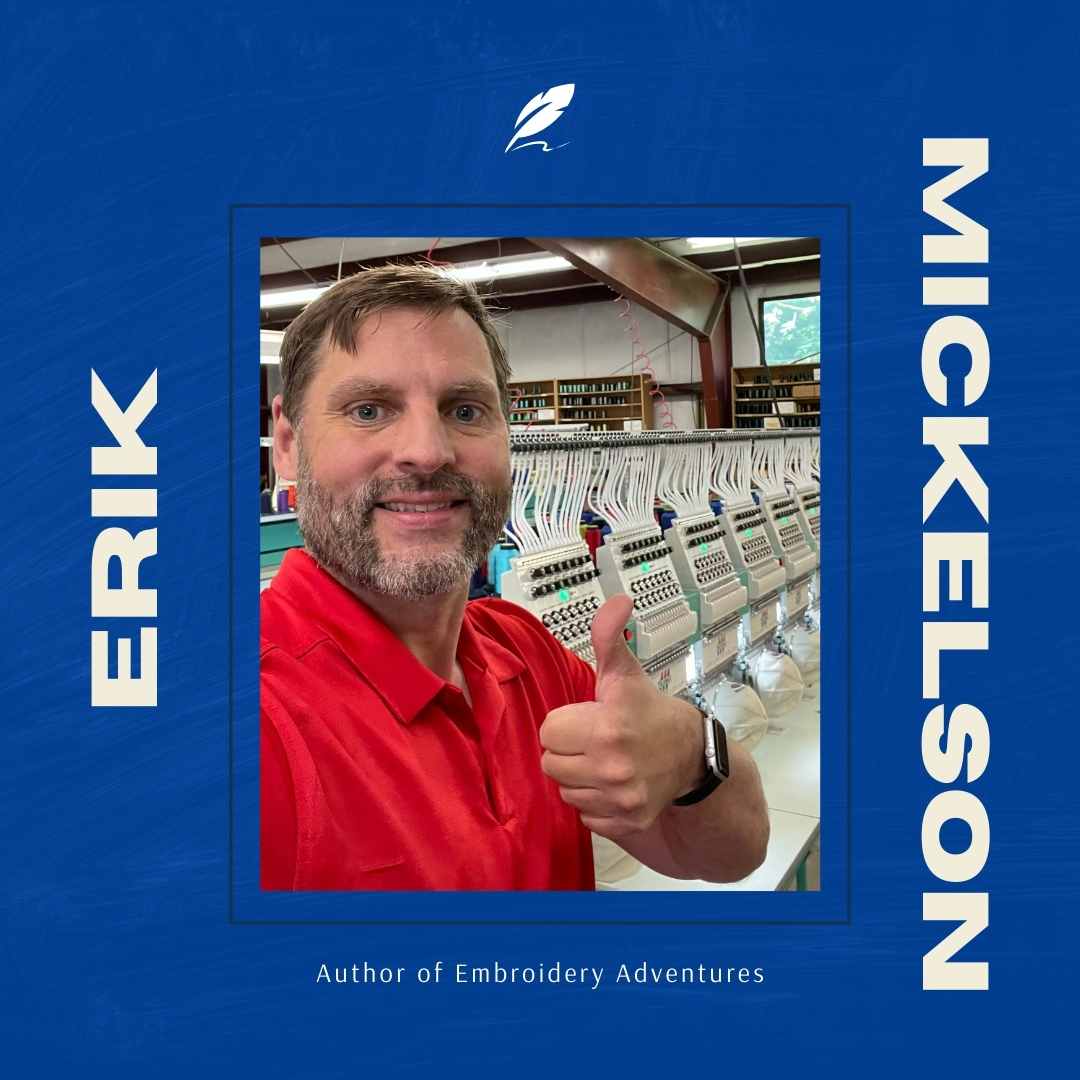

AuthorErik Mickelson ,the Operations Manager since 1996 is a 2nd generation embroider. Erik started fulltime in his family's company after is graduation from Washington State University in 1996. |