|

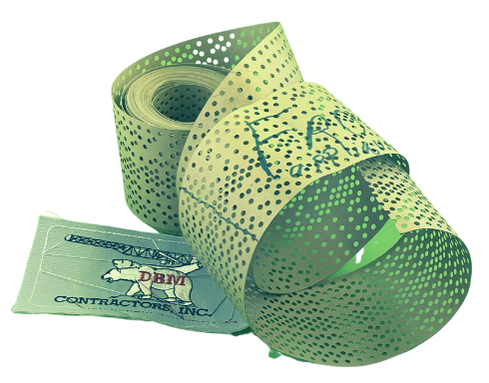

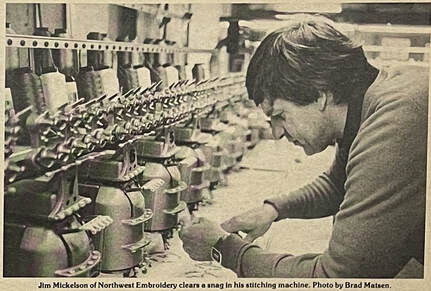

The Journal, June 1981 by Brad Matsen  The Beginning An American skipper who I recently fished the Bering Sea in a joint venture with the Soviets came home grinning about the way he and his cronies had surprised the foreigners with monster tows and plugged processing ships. He said the Russians were a little slow to pick up on the sharpness and fish the wisdom of the American draggers, and to strengthen his point, he whipped off his elegant sable hat and said, "Here look at this. Those guys were so lame they traded this or one of that whadda you call ems, you know," he reached for the words. "A goddamn baseball hat." "Gimme one of those hats" Long before baseball hats went to sea, the fertilizer, seed, and machinery salespeople in the brown dirt bible belt were passing them out to farmers. "Gimme one of those hats, will ya," was a good way to say hello to a salesman. And the salespeople, confronted with the straight-laced men in three-syllable Jesus country was glad they had the hats in a territory where their regular handouts-booze and girlie calendars-were verboten. John Deere to Rock Stars The hottest items on the promotional baseball hat scene for the year were from John Deere, Cat Diesel, and Ralston Purina, and the people who wore them were those who used the products the hats touted. Then about ten years ago, the hats became chic, and rock stars wore them on album covers. Since then, it's been a hat city, especially in the seafood industry. One-for-one trades are common, and processors, suppliers, and fishers' groups buy them by the gross to pass around the fleets. Naturally, somebody has to make all those patches and hats, and in this part of the country, they come from an unassuming company on a Tacoma side street. Northwest Embroidery was started in 1977 by Jim Mickelson and Ray Roger, who knew a good thing when they saw it. Alaska Leads to Japan At the time, Mickelson was working for ARCO in Prudhoe Bay with a crew of 110. At the end of the stint in the arctic, Mickelson ordered hats for the whole team as keepsakes, a kind of thank-you for good service. The hates said, "Prudhoe Bay Alaska, Keep America Independent," and they were a big hit. When Mickelson tried to find a bargain for his second order - by this time, he was selling the leftovers for $5.00 apiece, and he found out that no one was manufacturing the patches in the Northwest. Mickelson, who is a very up fellow in his late thirties, saw a hole that needed filling, " I checked all over the place about buying the equipment to stitch the patches and finally came across a Japanese company that made me an offer I couldn't refuse," Mickelson said. He had been working for the oil company for over a decade and wanted to take a chance. As his inquiries progressed, Mickelson also confirmed his plan to leave ARCO after getting the business rolling. "The guy from Barudan (the Japanese company) called me up when he heard I was looking around and told me to come to North Carolina to look at a typical machine in use, " Mickelson said. "I said to myself, "What the hell is this? I'm the buyer. They should come to me," but like he was reading my mind, the guy says, "You like to make money? You come down here and see this machine. We'll teach you everything you have to know, and if you go belly-up within one year, you get your money back." Patches and Blue Jean Pockets The machines performed as advertised, proving to be the latest technological marvels in an old traditional hand-work trade. With a punch-tape programmer and batteries of automated stitchers, a company like Northwest can simultaneously embroider dozens of patches, blue jeans pockets, or any other fabric. On the horizon, according to Mickelson, are sewing instant patches for the walk-in custom trade. In such an operation, the patch pattern and wording would be punched into a typewriter-like keyboard and transferred directly to the stitcher. While Mickelson was discovering how to produce the hats, Ray Rogers worked some small miracles developing markets to launch the business. Mickelson and Rogers own a tape programmer and three stitchers and run the entire operations with 15 employees in two shifts. Mickelson estimates that he can turn out 150 patches per hour, and the company has taken off. "It was good right from the beginning," said Mickelson, who is building a new plant in the nearby Milton this year. "We stress quality, satisfied customers, and high-grade America-made caps. That formula has worked for us." Quality in every Stitch Each patch takes from 1,500 to 15,000 individual stitches to produce a design. Mickelson's tape programmer, a young man, named David Saunders, traces over a design drawn six times life-size, outlining every stitch. "If I make a mistake," Saunders said, " I have to start over from the beginning. That isn't very good. An artist can erase a mistake, but not me." From Saunder's tracing, the computer makes a wide, perforated paper tape that calls the shots for the stitchers. A test patch is then made to check the design and the programming, and the multiple stitchers go to work. Jimmy Carter Shows off his Cap Mickelson confesses that he has yet to produce a hat for Northwest Embroidery but says he's proud to have outfitted Jimmy Carter and Ted Turner. "We made two hats for Carter and destroyed the tape," Mickelson said. "They wanted it that way. The Union group sponsored his visit has one, and Carter has the other. "Carter was delighted with the hat," Mickelson said, "Even he is subject to the identity syndrome as I call the desire to wear logo hats." Everybody wants to be part of something. If an employer gives a person a hat, they are usually proud to wear it. That seems to double in the fishing business. Design Punch TapeJim Mickelson "Punching" an embroidered designJimmy Carter wearing his cap produced by Northwest Embroidery

0 Comments

Leave a Reply. |

Categories

All

Archives

June 2023

AuthorErik Mickelson ,the Operations Manager since 1996 is a 2nd generation embroider. Erik started fulltime in his family's company after is graduation from Washington State University in 1996. |